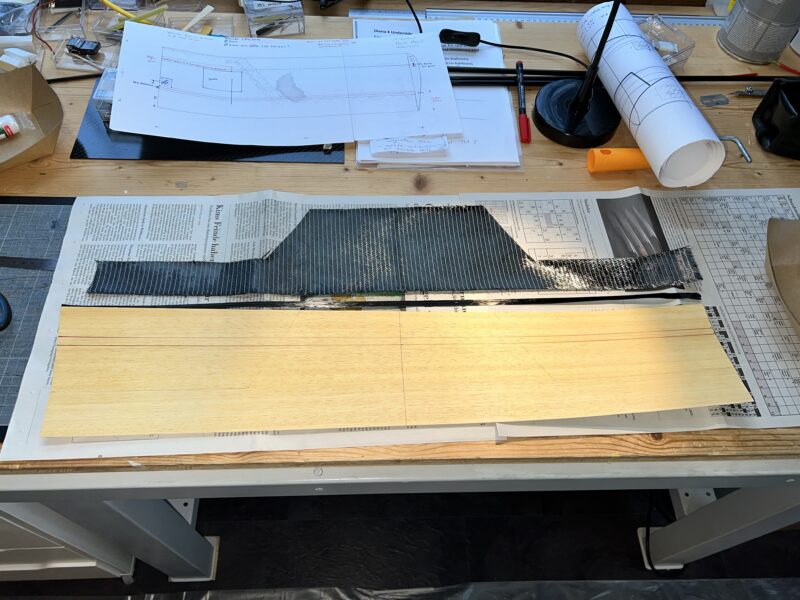

Last week I put both the upper sides of the wings in vacuum. On Monday I prepared the layout and spars for the first wing. Today I “closed” the first wing, with help from my flying buddy EP.

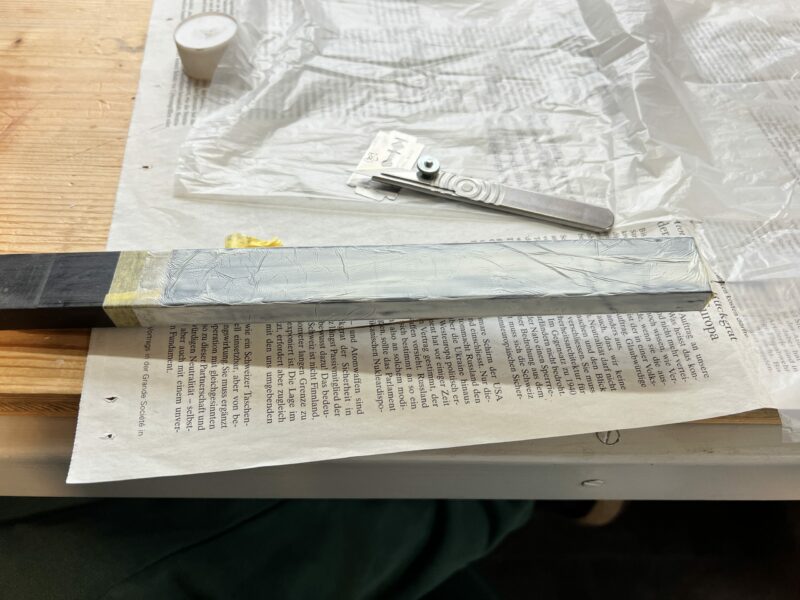

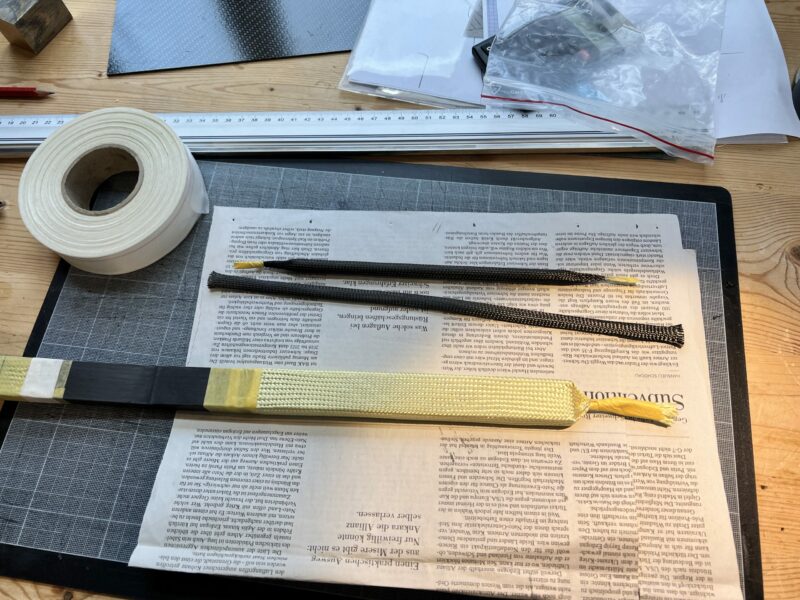

Preparing the spars was a bit more work than usual as I had to do the calculations for the amount of carbon rovings on the main spar and decide on depth of the control surfaces. I used in total 2×19 rovings at the root and 2×2 rovings at the tip, distributed using Christian Baron’s helpful excel sheet. The width of the main spar is 25mm at the root and 6mm at the tip. I used three different types of carbon sleeves around the main spar, a 3k for the first third and 1k sleeves for the middle and outer third. The amount of rovings at the root was determined on the basis of the space available after deducting the space required by the wing joiner and sleeve. I’m curious to see how heavy the first wing will be.

You must be logged in to post a comment.