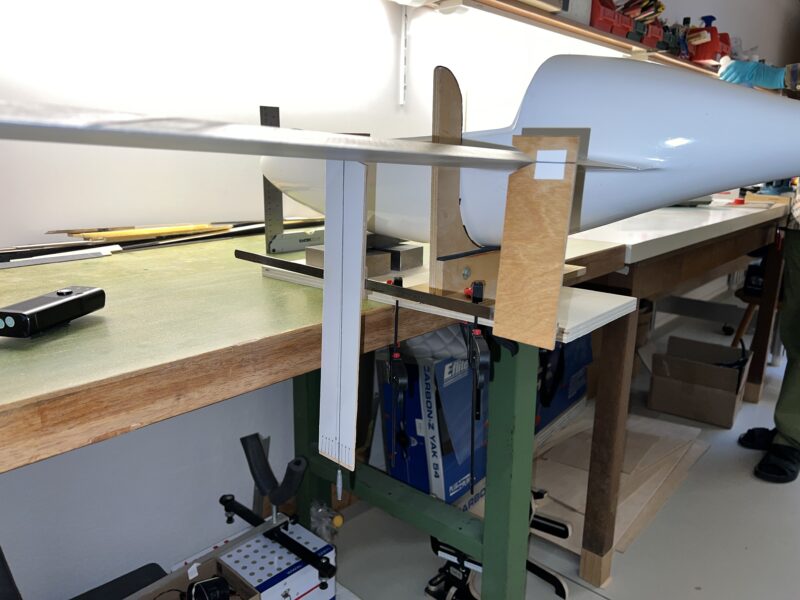

Work on my Monerai has been progressing steadily over the past few weeks and I hope to have it ready to maiden in the next few weeks.

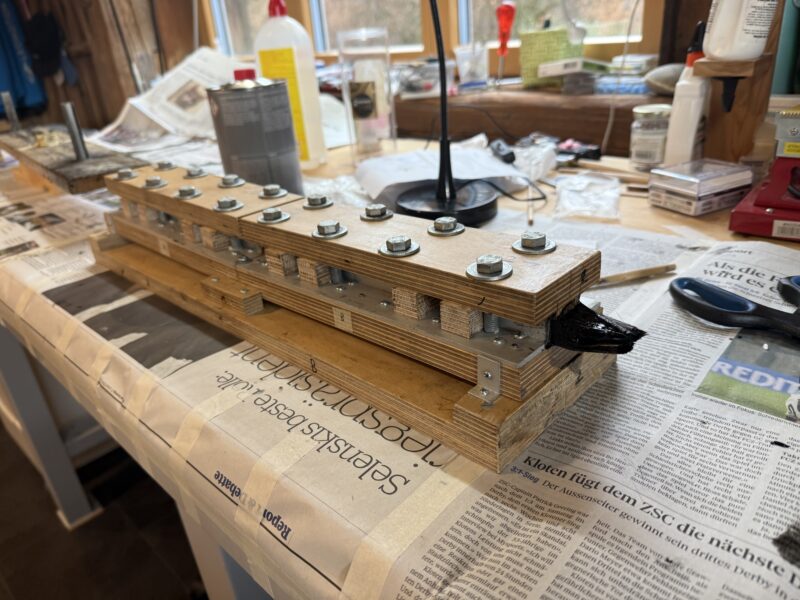

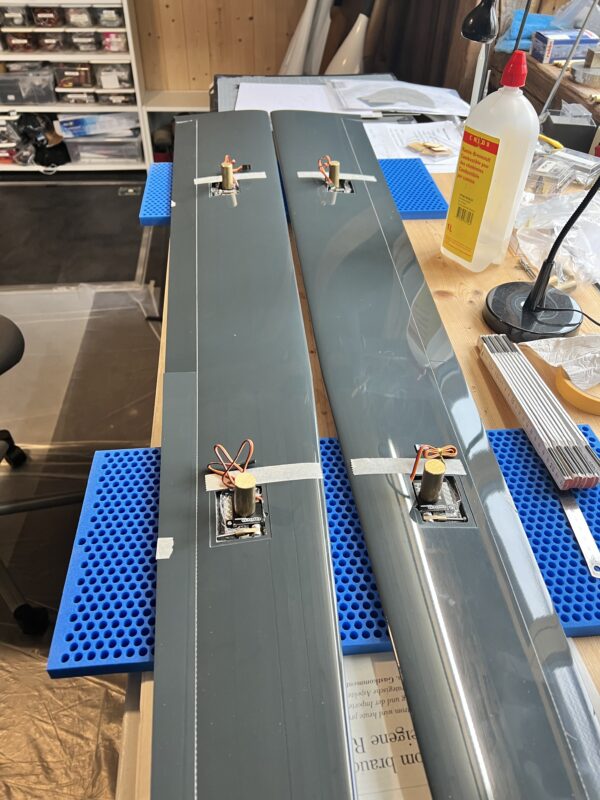

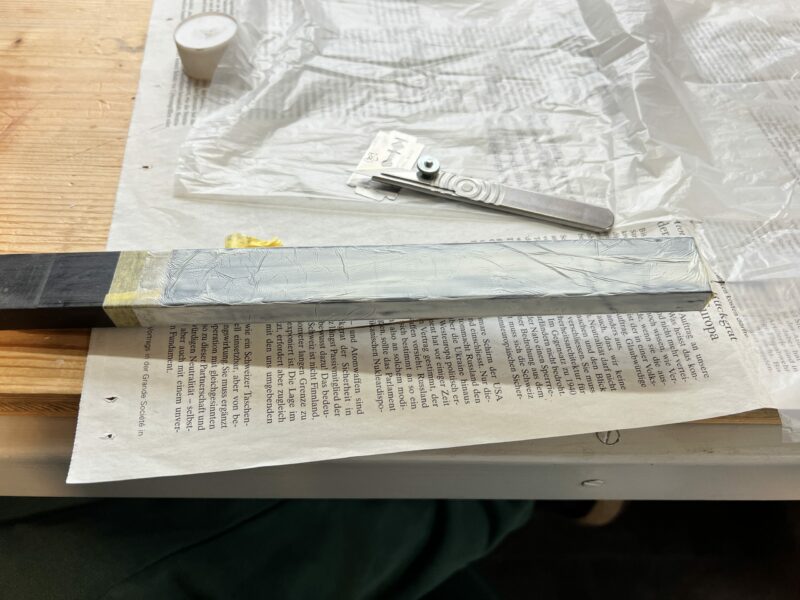

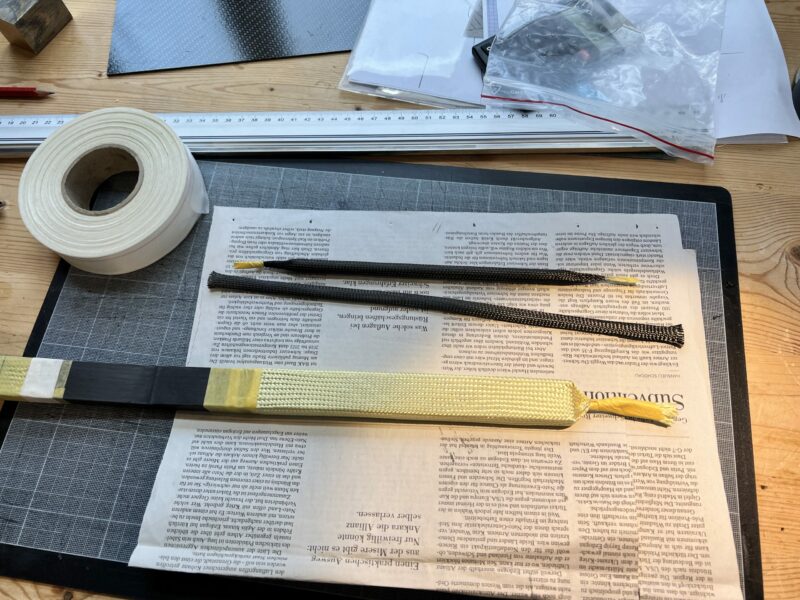

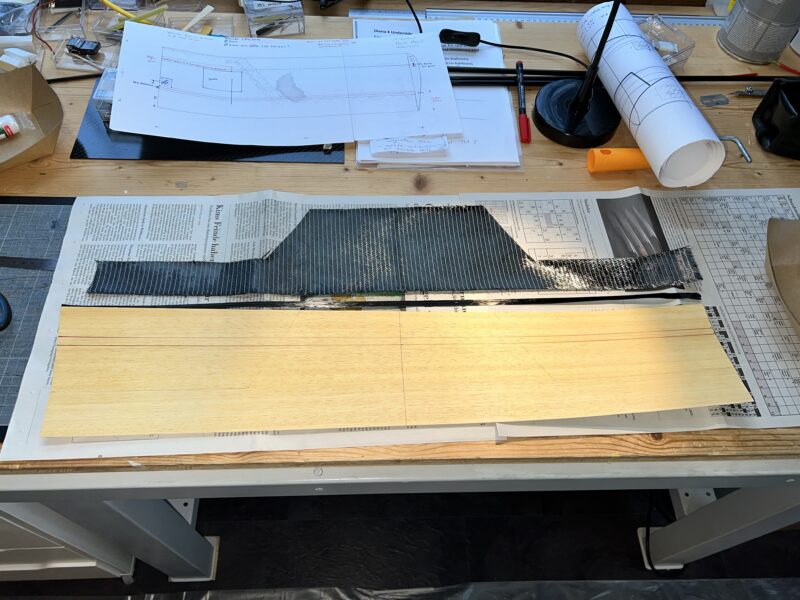

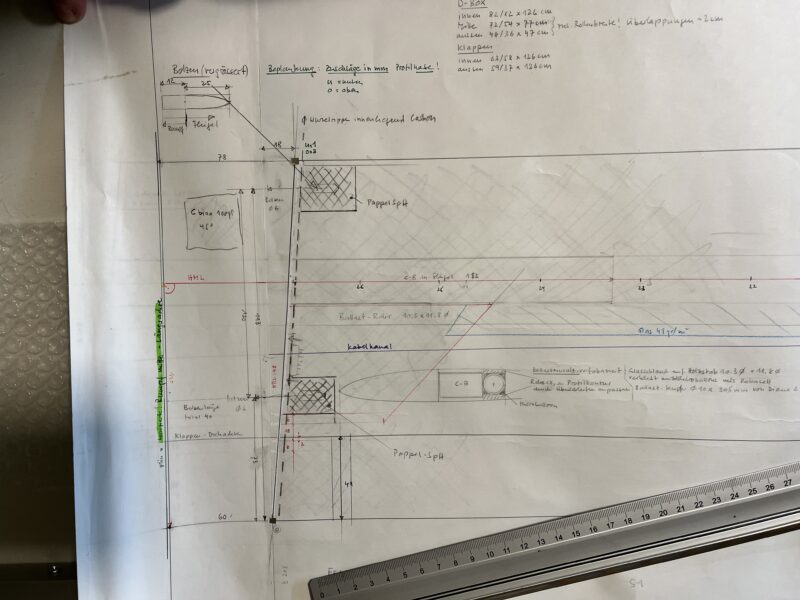

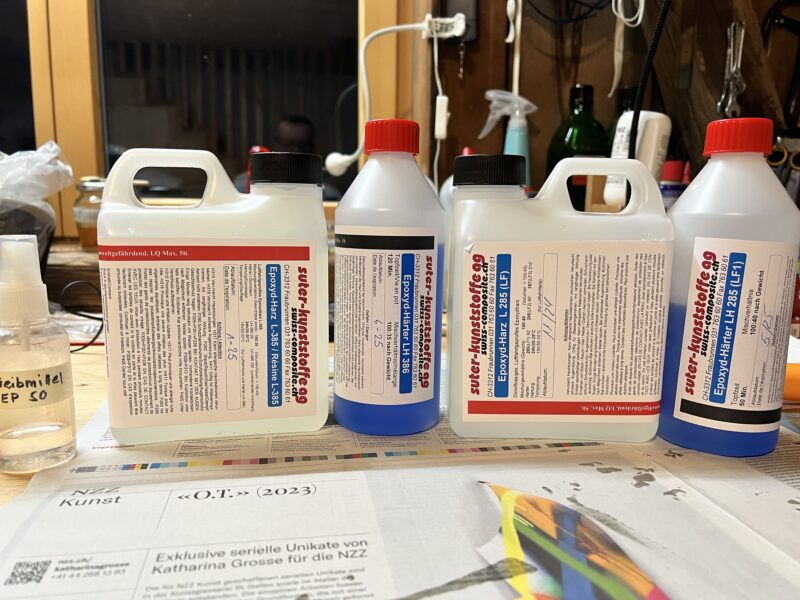

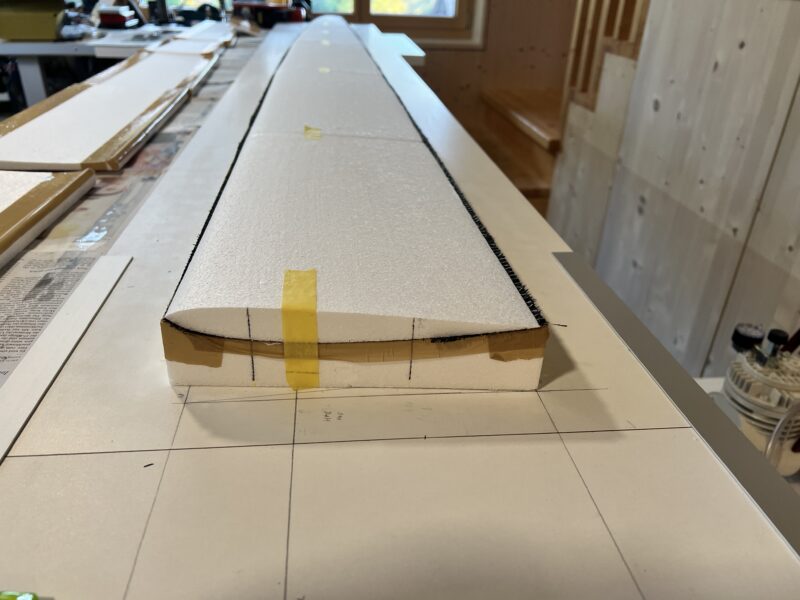

The wing control surfaces have been cut out. I sanded bach the part where the control surfaces move under the wing when the surfaces are deflected upwards. After sanding I glassed it with 50gr glass, which was then again lightly sanded to keep it as thin as possible and allow the largest possible upward deflection. The control surfaces were then glued to the wing using silicon.

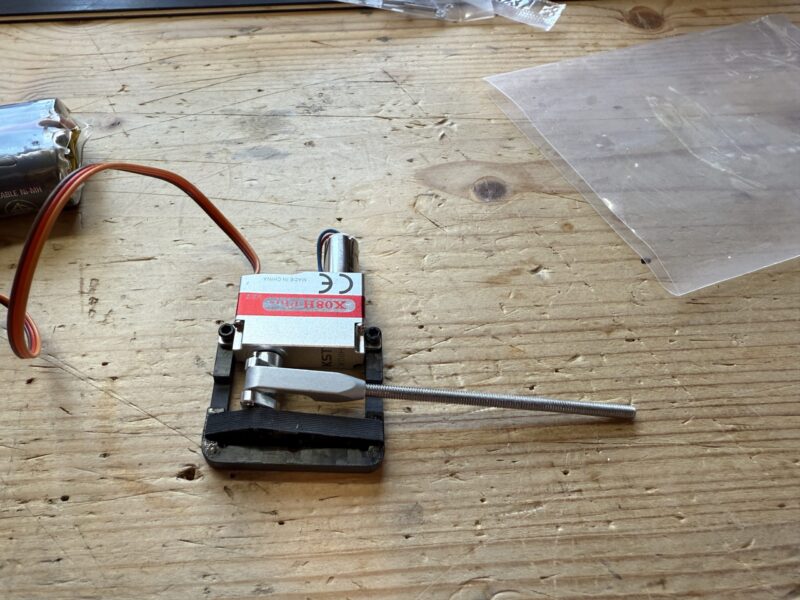

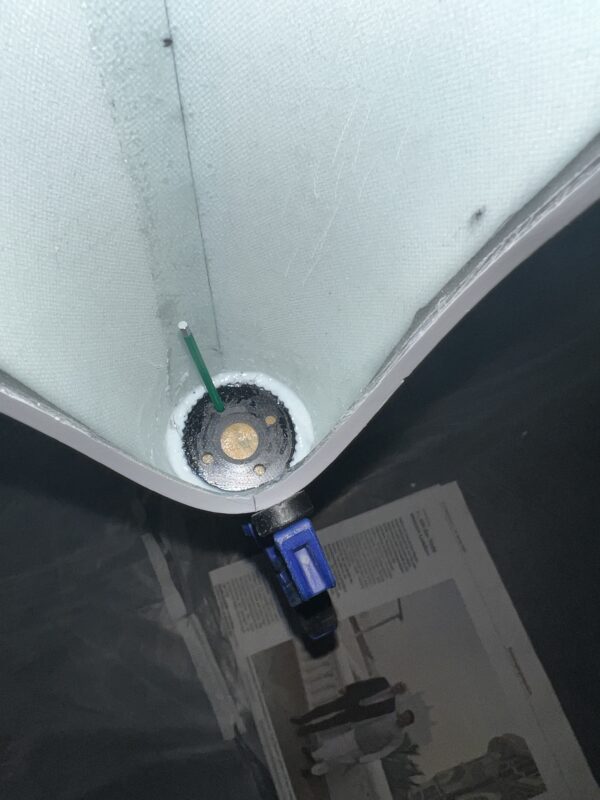

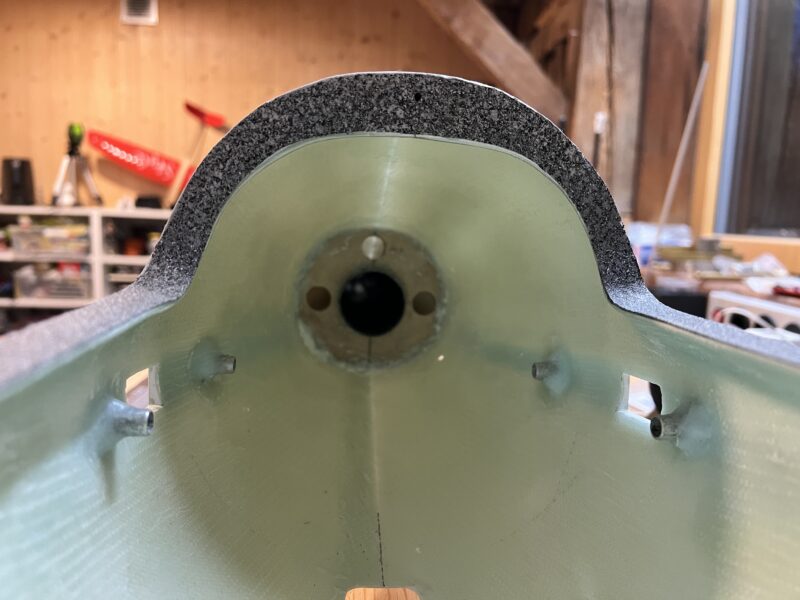

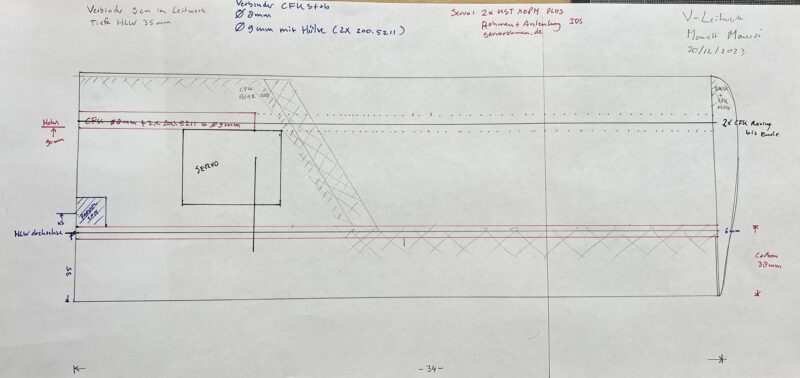

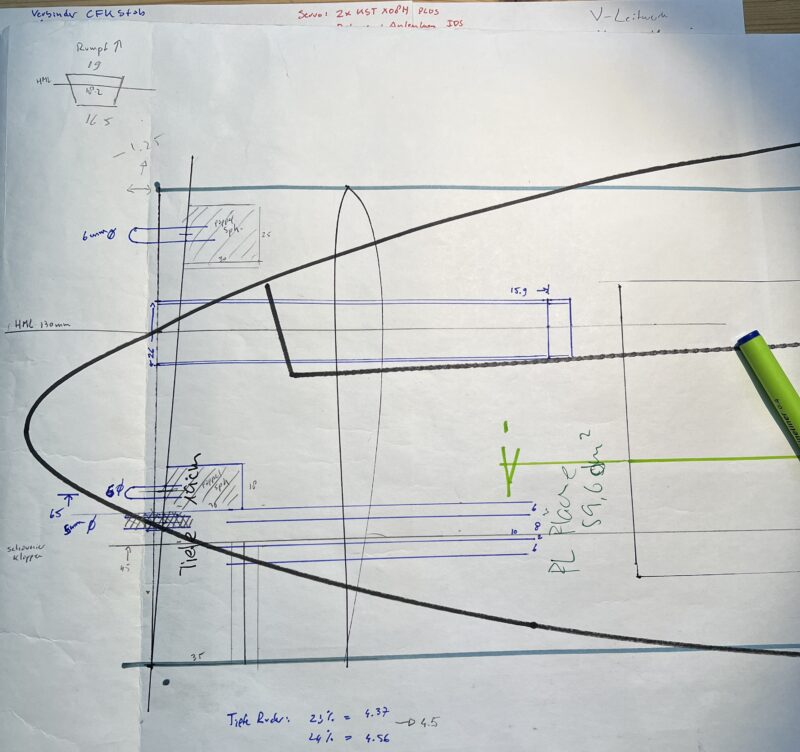

While waiting for the silicon to cure I finished work on the tailplane, wiring and fuselage. In the V-tail I installed two KST X08H Plus servos, which are light and relatively powerful. To avoid any play I splashed out on the expensive but really nice servo frame and LDS kit from Tomas Liu Studios. Rather than installing this as LDS I used a normal clevis and a carbon control horn in the control surface. It’s the first time I am using this set. Unfortunately the aluminium servo had a bit too much play on them, but I managed to reduce that to almost nothing using a drop of locktite. I’m pretty pleased with the final result, the installation is pretty tight, using the full throws of the servos, there is virtually no play and the setup looks good as well. The tips of the V-tail were painted dark red. I’ll do the same with the wings once these are done.

Power for the glider comes from 2x 2S LIPO batteries, reduced to 7.4v through a Hacker/Emcotec Dualbat DPSI (with magnetic switch). I’m using this system for all my gliders and am very happy with it. All the wiring has been prepared, I’m waiting until the wings are finalised to balance the glider and deterimine the final position of all the components.

I weighed the total setup, and I expect the glider to have a flying weight of around 3.6kg – including around 60gr of lead in the nose. Pretty good.

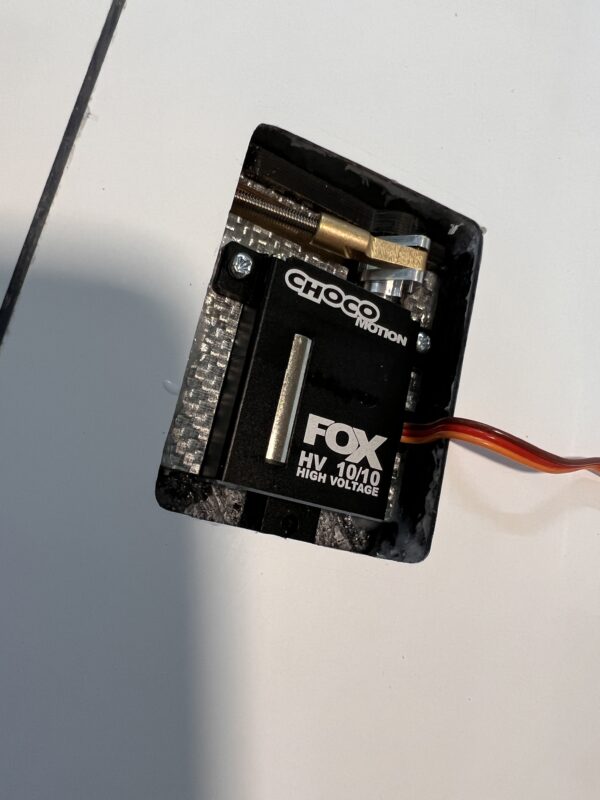

All that remains now is setting the seals for the control surfaces of the wings, installing the servos and then finalising the programming.

You must be logged in to post a comment.