The electronics setup of a glider is very personal. There are many ways to do it right – and at least as many ways to get it wrong. This “how to” contribution sets out the latest “state of play” on how I do things. This is by no means the best or only way to do it – it’s just the way I prefer to do things, based on my experience, requirements, skill set and availability of materials. Other layouts may work just as well for you. I purchase most of my components through Chocofly, Leomotion (both of which are located near where I live and are companies run by passionate pilots that I know and trust) as well as AliExpress.

Tools

Good tools are essential for building an RC glider, and also for doing the electronics. The three tools I use most are my soldering station, my crimping tool and my servo tester.

I’ve gone through various cheapo soldering rods (and many badly soldered connections) before I (finally) decided to splash out and buy myself a decent soldering station, following recommendations from colleagues.My Weller PU-81 is not cheap, but definitely worth it’s money. It heats up very quickly and holds the heat very well. Equally important is a good crimping tool. I’ve gone through various of these (including some expensive ones that were no good) until I found a cheapo one with HobbyKing. It’s the one I’ve stuck with since. Many of my colleagues buy their crimped wires and solder plugs onto extension wires. I prefer to do most of the crimping myself. It takes a bit of practice (there are enough online videos that show you how to do it), but making a wiring harness is so much easier when you know how to do it yourself. Also important is a good servo tester. There are many of these around, my prefered one is the Chocomotion/Fox version, which is identical to the KingMax version. Unfortunately I’ve yet to find a servo tester of which the centering point is identical to that of my Futaba receivers. When installing wing servos I therefore use a receiver to correctly center the servo, to ensure that the wing servo is mechanically centered and doesn’t need adjustments through the transmitter.

Plugs and wiring

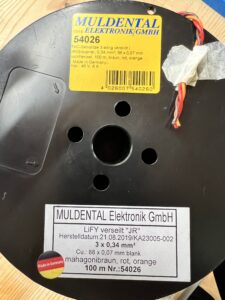

Pre-manufactured wiring with plugs is readily and cheaply available on the net. I always have several sizes in stock, for instance to connect telemetry sensors or to extend servo wires in the fuselage. Most of the wiring I assemble myself. My favourite brand of wiring and servo plugs is Muldental. I have a huge roll of Muldental twisted servo wire and Muldental servo plugs. I also have some cheaper servo plugs that I use for “non-essential” connections. Note that I usually solder my servos onto the wiring harness – that allows me to shorten my wiring, saves weight and avoids potential plug faults).

Apart from the servo plugs I also use 9-pin D-Sub plugs for connecting the wings to the fuselage. I’ve learned the hard way that it’s worth spending enough money on these plugs. The cheaper ones start failing after a few years. Get the more expensive ones (I pay around EUR 7 each), with gold plating and a higher number of connections rating. I always install the male (pins) into the wing and leave the female one hanging out of the fuselage (removing the metal casing). For wing with four control surfaces the green “Multiplex” plugs also work very well. For the motor batteries I use 4mm bullet plugs – the version with the open end (I usually fly with a 2x3S setup that needs the two batteries to be linked in series). Occasionally I also use XT60 or XT90 plugs (towplane). For all these plugs (except the D-Sub) my favourite brand is Amass – excellent quality, good value and easily obtainable online.

Electronic components

This is probably the most personal part of all – and something that’s continuously evolving as new components become available or as I learn to trust – or not – existing components.

Despite recommendations from colleagues to switch to another transmitter system (many colleagues have switched to JETI or Radiomaster), I continue to use a Futaba transmitter (T18SZ), usually in combination with one or two R7008SB receivers. Futaba has always been very reliable and I’ve now invested so much money in receivers for my aircraft and time in programming them that switching is not really an option. I’m also very familiar with the programming and like the logic behind programming a Futaba. Another important factor is that Futaba continues to be the most used system in our club, making it easy to assist colleagues with programming or buying/selling planes. It’s frustrating to see though that Futaba hasn’t really been investing much in updating its transmitter systems to keep up with the competition. If I’d be starting the hobby now the I would probably go for JETI.

My favourite servo brand is Chocomotion/Fox. All my first builds were using Futaba Servos, but unfortunately Futaba hasn’t updated its major servo ranges for ages and the technology is now outdated. The Chocomotion/Fox servos are way more powerful – important with the newer LDS systems (I’ve had several Futaba malfunctions, including one massive shortcut resulting in a melted servo and a near crash of my self-built Diana2). Moreover, many of the Chocomotion servos have “soft adjustment” (softly returning to center rather than jumping back when switched on) as well as a servo overload/switchoff built into them (servos switching off rather than burning or overheating), thus significantly reducing the risk of malfunction and damage to the glider. Importantly, they are also good value for money. I’ve had many malfunctioning servos over the years, but Chocomotion has so far served me best. Chocomotion servos continue to evolve and improve – getting more powerful and reliable all the time. The newest generation of Chocomotion servos now also comes with servo plugs directly on the servo. I’ll be using these for my Monerai build and will report back on my experiences there. I also have good experiences with the later generations KST servos (the older 1-series wing servos as well as the X08 V1-3 were crap) and excellent experiences with the (expensive) MKS servos. I’ve not used other much-hyped servo brands like Chaservo so far.

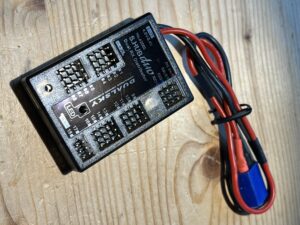

My favourite ESC brand is Dualsky. My most-used ESC is the Summit 100 Light. The advantage is that this doesn’t need any programming (the motor brake can be done through the programming of the transmitter) and, importantly, has an 8A BEC. A further advantage is that it functions perfectly with the Dualsky motors that I use in most gliders. Until recently I mostly used the Caste 100 Light, which is a great ESC and very easy to program, but I’ve found the 5A BEC to be just short of what the newer generation of servos needs. I’m hoping that Castle will come out with a new generation at some point though. Also easy is that the BEC voltage can quickly be set through two dipswitches. I usually run my onboard electronics at around 8v.

Also handy is that the Dualsky ESC comes with a capacitator included in the package – an essential component for every setup using newer high voltage servos. These servos supply power back to the onboard electronics if they are moved or under pressure. Club colleagues have run some tests with this – with very worrying results. These return currents can cause the receiver to briefly reset itself – and thus leave the glider without control for a brief moment. A capacitator installed into the electronics, close to the receiver, equals out power peaks in the system and avoids such reset. The Dualsky Summit 100 Light has a good quality capacitator included with the ESC. I plug that capacitator into the S.Hub next to the receiver(s).

For most of my gliders I use a power and receiver redundancy/backup system. For the receiver backup system my favourite option is the Dualsky S.Hub Duo. This allows me to connect two receivers to the hub over an S.Bus connection, with the Hub automatically choosing the strongest signal of the two. It also allows me to connect more than 8 channels to a single receiver. For the power of my electronics I always use the ESC’s BEC as the primary source. I then solder a backup power system into the power connection between the S.Hub and the ESC. My preferred option is the Scorpion Backup Guard II in combination with a 2S LIPO battery. The advantage of this option is that the Backup Guard automatically recharges the LIPO when it’s connected but not in use. If the system power drops under 5.5V then the Backup Guard automatically kicks in and provides the system with power. I program my transmitter’s telemetry function so that it gives me an alarm if the onboard power drops below 5.8V so that I can quickly land the glider.

You must be logged in to post a comment.